Managing Legionella Risks After A Pandemic

As commercial/non-residential buildings that have been vacant for several months due to the COVID-19 pandemic return to use, care needs to be taken to prevent inadvertently exposing employees and the public to another respiratory risk factor: Legionella. Legionella is the bacterium that causes the serious and sometimes fatal respiratory infection Legionnaires’ disease. Generally present in local water sources in benign amounts, Legionella microbes are capable of colonizing in warm non-circulating water systems and becoming disease carriers through widespread inhalation of contaminated mist or vapor by building occupants.

Conservative estimates of annual Legionnaires’ disease outbreaks range between 8,000-18,000; however, the extraordinary impact of the novel coronavirus has the potential to skew these numbers dramatically without rigorous proactive measures. Investigations by the Centers for Disease Control and Prevention (CDC) show that almost all outbreaks would have been preventable with more effective building water management.

In the current pandemic period, building owners can take immediate actions to prevent unsafe water supplies from being put back into service upon reopening for business. While there are no government or industry standards pertaining to the pandemic shutdowns specifically, guidance is available to help building owners understand the precautions they must take now to restore domestic hot water systems to healthy conditions after a prolonged period of stagnation.

To that end, Purdue University has synthesized the peer-reviewed, government, industry, and nonprofit literature relevant to the implications of water stagnation on plumbing systems and decontamination practices for water quality and health, and compiled a primer of large building plumbing preventative and remedial strategies that can drive ongoing efforts to develop recommissioning guidance.

Flushing Water Systems After A Period of Stagnation

Before returning buildings to occupancy after this extended period of little to no water usage, it’s critical to thoroughly flush the building water system and devices that could be affected by stagnation risks with fresh water. How this is best achieved depends on the size of the building, the size of the service line, the type of water heating device, and the actual plumbing design and distance from heating source to furthest outlet fixture.

In addition, knowing what constitutes “fresh” water and how to measure it is key. Fresh water has the right level of residual chlorine for disinfectant purposes and dissolved oxygen combined with the recommended temperature level. The Center for Plumbing Safety at Purdue University offers a downloadable list of flushing plans and other resources to help navigate this process and prepare a flushing plan. This Purdue video provides an excellent overview of the considerations.

Guidelines for Temperature Safety

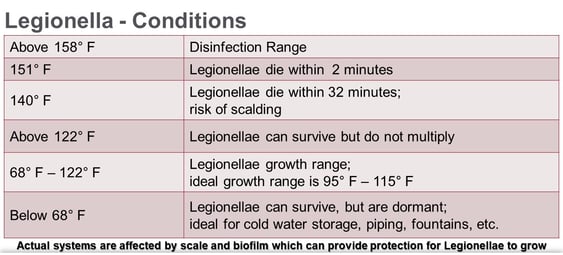

ASHRAE Guideline 12-2000, Managing the Risk of Legionellosis Associated with Building Water Systems, is a comprehensive guideline, under continuous maintenance, which asserts that Legionella survival and growth is temperature dependent. This guideline has more recently given rise to ANSI/ASHRAE Standard 188: Risk Management for Building Water Systems, which went into effect in 2015 and was updated in 2018 based on an understanding of the potable water temperature ranges under which Legionella grows, flourishes and can be killed.

For commercial/non-residential structures, Guideline 12 provides the temperature guidance below concerning (1) the storage water heaters and hot-water storage tanks, (2) the water fixtures and return pipes, and (3) the water between the heater and the fixtures. All three of these points must be addressed as described or the temperature could fall short of what is desired.

- Storage water heaters and hot-water storage tanks should be adjusted or maintained so they deliver water consistently at or above 140°F (60°C) unless other compensating control measures are used. Because the water temperature in the storage tank is maintained at or above 140°F (60°C), measures should be taken to prevent scalding.

- Unless other compensating control measures are used, hot water should be maintained consistently at or above 120°F (49°C) throughout the hot-water system, including water for delivery to the points of use and in the hot-water return.

- Maintaining hot-water temperatures at or above 120°F (49°C) at fixtures has been used successfully as a Legionella control method; however, water temperatures must be consistently maintained above 120°F (49°C) between the water heater and the fixtures to assure a minimum of 120°F (49°C) at the fixture and in the pipes returning to the water heater. To prevent scalding, water temperatures at the tap may require additional control or adjustment at or near the point of use.

If you are interested in learning more about reducing the risk of Legionella in a building's water supply, register for one of our education sessions. Topics covered include:

- Legionella Basics

- Piping Material Comparisons

- Risk Prevention

- Current Water Treatments

- Chlorine Effects on Piping Materials