Choose the Right Plastic to Ensure Plumbing System Success

Merriam-Webster defines a plastic as “any of numerous organic synthetic or processed materials that are mostly thermoplastic or thermosetting polymers of high molecular weight and that can be made into objects, films, or filaments.”

It is all too common, when it comes to piping systems in building plumbing and hydronic HVAC applications, for plastic pipes to be lumped into one big category. But every plastic has its strengths and weaknesses with respect to given applications under varying conditions because every polymer is different from every other. The Plastics Pipe Institute counsels: “Users should check with piping system manufacturers to be sure that their products are recommended for each specific application and can be supported with design and installation advice.”

Readers have by now become aware of the recent news stories of PP-R pipe failures that have plagued building owners in corrections to high rises to hospitals. This article details just how severely the integrity of a system can be compromised by leaks, flooding and water shutoffs, to the detriment of the building’s ability to function as intended.

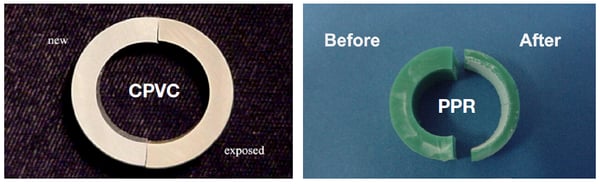

Any properly specified and installed plumbing system should last decades. But this is a tall order if it has been taxed from the outset with susceptibility to leaks. When PP-R is exposed over time to the hypochlorous acid that forms as a byproduct of chlorine water disinfection, the piping material can break down, becoming thinner and weaker through oxidation stress cracking that actually erodes material from the pipe walls.

Corzan® CPVC does not have this vulnerability because it is inherently resistant to the effects of chlorine. This puts the material in a well-done installation in the ideal position to fulfill the intended design life of the system.

Our recent blog post “Installed Costs Overview: CPVC vs. PP-R for Commercial Plumbing” outlined an extensive list of areas in which selecting CPVC over PP-R on an installed costs basis alone makes a lot of sense. But that is only one reason to give CPVC a detailed look. While it is true that both were originally introduced as chemically resistant materials suitable for industrial applications, the fact remains that for the most common types of commercial and hydronic installations, iron pipe size CPVC outperforms PP-R and many other plastics for its sheer range of desired attributes:

- Strength and durability

- Chlorine resistance

- Reduction in biofilm risks

- Safety in use

- Installation ease

- Does not support combustion

Unsure of how to get started working with Corzan CPVC Piping? We are ready for a consultation when you are.