Why CPVC Pipe Fails, and Why It Succeeds

A question commonly asked about CPVC piping is what could cause a failure once it is in service. It is not necessary to have a materials science degree to gain an understanding of the factors involved. Essentially, certain conditions must be present for a failure to be set into motion. In this post we will look at what these conditions are and how they may interact with each other.

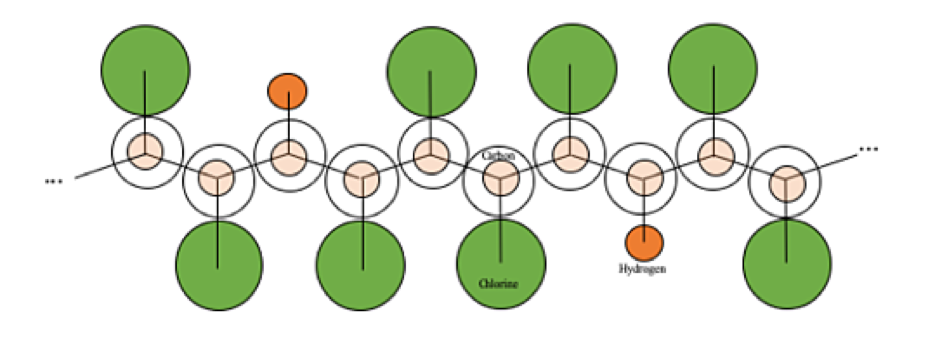

CPVC is an amorphous polymer that is comprised of long chainlike molecules tangled together. Most chemicals by themselves are not aggressive enough to disentangle these chains single-handedly. Those that can are meant to disentangle the chain in order to do their job. An example of this is solvent cement, which works without any mechanical stressor when applied correctly and in the exact amounts specified. That’s because the chemical the solvent cement contains, tetrahydrofuran, is actually a true solvent or plasticizer for CPVC.

There is a range of chemicals, however, which either (1) have a limited ability to separate the polymer molecules and therefore require a lot of stress to be exerted to complete the disentanglement (e.g., ethylene glycol), or (2) are more readily effective at disentanglement and require only a little added stress to pull the polymer molecules apart (e.g., methanol). When the chemical is on this latter end of the spectrum, it is considered to be more “incompatible”.

A molecule of CPVC

When a chain breaks, one or more things may have occurred, although typically no one factor by itself creates an issue:

- Stress or damage from strong external mechanical impacts from installation or operating conditions (improper storage, joining or hangers that are too tight, for example);

- Contact with incompatible chemicals, from the outside and/or the inside;

- The two above combining to overcome the strength of the material in a phenomenon known as environmental stress cracking;

- The quality of the original polymer resin was suboptimal, such as may be the case with a generic CPVC raw material;

- The manufacturing process to produce the part was not tied to a stringent quality assurance program.

How System Designers and Installers Can Take Control

Formal investigations of CPVC pipe failures reveal that problems begin with something as basic as a general disregard for the pipe manufacturer’s installation recommendations with the resulting poor workmanship. Coupled with other factors from the list above, the status quo for the piping system can be a lack of resiliency right from the start.

Failures occur when the combination of stresses exceeds the strength of the original material that has already been reduced by quality issues or chemical stresses. The reverse is also true: high-quality processed CPVC may be able to withstand some mechanical stress and contact with chemically incompatible materials. Thus the CPVC compound specified should have a reputation for consistently exceeding the minimum strength standards.

That’s why it is important to know that Corzan® CPVC has significantly higher pressure ratings, tensile strength and impact strength than the minimum requirements of various applicable standards, setting it up for a successful installation and service performance from the start. All Corzan CPVC partner manufacturers are selected based on their proven track record of reliability. To guarantee consistent and high quality production, each is contractually required to participate in our Quality Assurance Program.

For more on understanding chemical incompatibility, you can read a white paper on the subject by a Lubrizol materials scientist and find FBC™ System Compatible Products.